All through the previous years, we’ve had the privilege of revealing a number of breakout unbiased watchmakers, usually by means of their first watch. Typically, although, we even get to see commencement watches, or ‘montre ecoles‘ up shut and might showcase younger abilities even higher. This time round, we’re somebody in a good earlier stage of his profession. Simply 19 years outdated, American-born Hudson Mickey continues to be honing his craft as a watchmaking pupil however already has an attention-grabbing story to inform. As an instance, Hudson goals to construct a complete motion from scratch after graduating. So, to say he’s formidable is an understatement! Nevertheless, earlier than we go that far down the highway, we determined to ask Hudson a number of questions on his training, passions and future concepts.

Robin Nooij, MONOCHROME Watches – Hudson, you’re nonetheless in watchmaking college and a few 12 months away from commencement. How has that been for you up to now?

Hudson Mickey, pupil watchmaker – College has been profoundly useful, much more so than I imagined. I’d pursued watchmaking for 4 yearsbefore coming to the Lititz Watch Technicum. It seems like I’ve greater than doubled my collective data about watches already, and I’m solely midway by means of this system. Till you’re in it, you don’t fairly think about the influence of spending all of the attainable hours in every week specializing in watchmaking alone. There have been so many abilities that I by no means had the prospect to study earlier than, both from lack of instruction or from not having the instruments, and the abilities I had discovered earlier than coming to high school have since improved tenfold. The principle factor is that every little thing—from what they educate to how it’s taught—modifications the lens from which you see the mechanics. They educate you learn how to suppose like a watchmaker.

What sparked your curiosity in mechanical watchmaking, and what individuals and/or watches encourage you?

Again after I was twelve, I inherited my great-grandfather’s highschool commencement watch, which was an outdated rectangular Bulova. My grandmother discovered it in a field stuffed in her attic, together with a number of his different belongings. It was the primary piece of jewelry I ever owned, so I turned fairly infatuated with it. I spent the following few years on and off trying into any info I may discover on it; that’s what spawned my preliminary intrigue in watchmaking, because it obtained me watching movies that defined the distinction between mechanical and quartz, studying about totally different motion frequencies, issues like that. My studying actually picked up tempo and began taking over most of my time after I was fourteen, and I’ve been pursuing it full pressure ever since.

Are you able to inform us a bit about your background up to now?

I’m a nineteen-year-old watchmaker in coaching, initially from the Central Coast of California, and am at the moment attending the Lititz Watch Technicum in Lancaster, Pennsylvania. I started taking native watch restore lessons at fourteen from a small jewelry retailer in my hometown. These began in direction of the tip of my sophomore 12 months (the 2nd 12 months at an academic institute) in highschool, nonetheless throughout COVID. In direction of the tip of summer time 2022, I did a six-week internship at J.N. Shapiro Watches in Los Angeles. On condition that I had solely unofficial expertise from the mom-and-pop jewelry retailer, Josh and his workforce took an enormous danger bringing me in in any respect, not to mention for thus lengthy. I’m ceaselessly in debt to them for that, as these six weeks have been actually what pivoted watchmaking from being a devoted pastime to what I needed to pursue with my life.

It’s also the place I used to be first launched to high-end ending and the place my first makes an attempt at beveling came about, which now has change into my main focus. After that, I went again to complete highschool, graduated in June 2023, and utilized to a watchmaking college as a substitute of the extra conventional faculties. Over that summer time, I spent two weeks in Switzerland, and I used to be lucky sufficient to go to Philippe Narbel’s workshop in Vallée de Joux. Nonetheless solely seventeen on the time, he was variety sufficient to take me in for the entire day and educate me his strategies of beveling, letting me practise at his desk and use his instruments. I additionally attended his beveling masterclass, which he held in Los Angeles in Might of this 12 months. I got here to LWT straight out of highschool, and I’ve been there ever since.

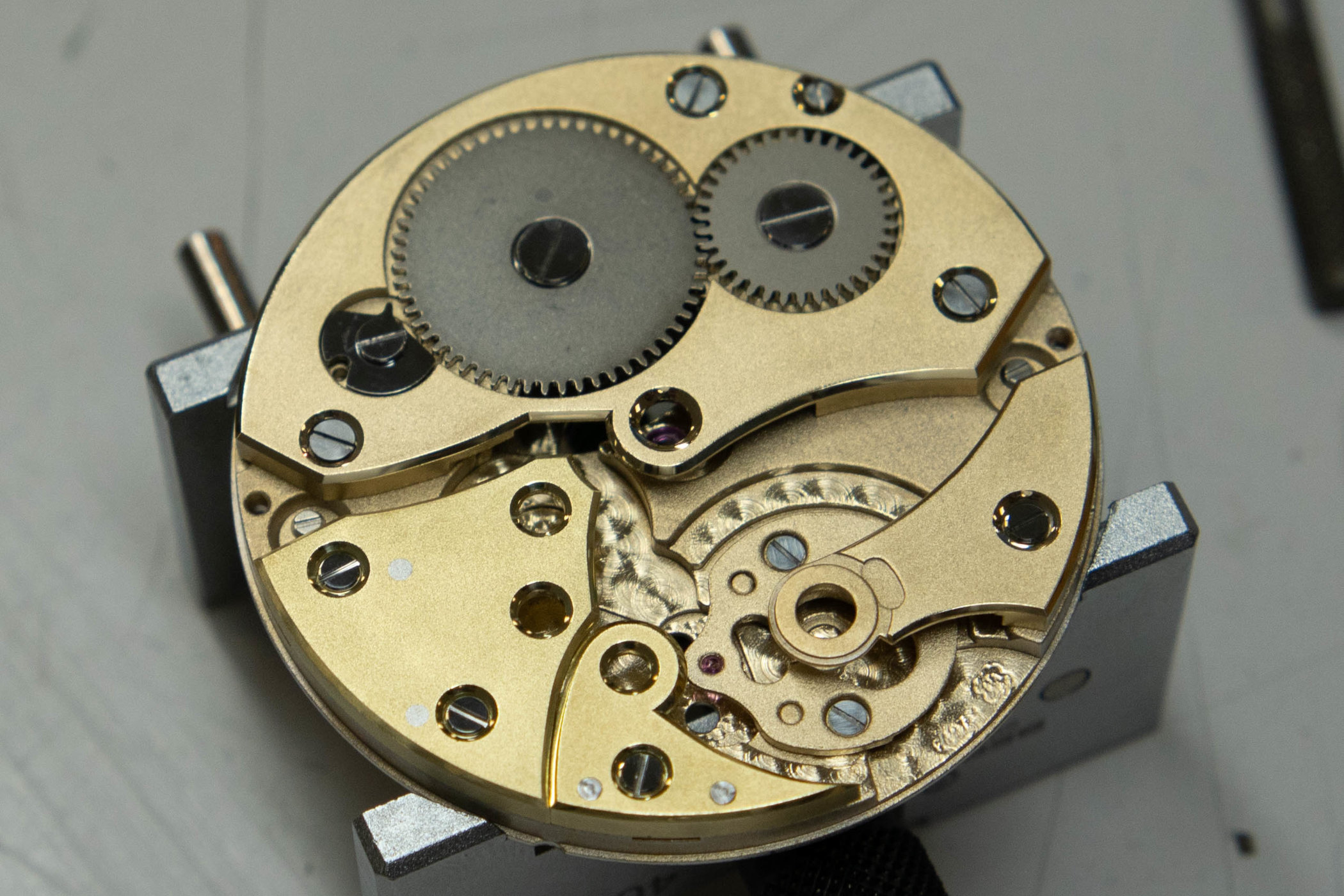

You’ve simply completed your college watch, which we will see within the photos. Are you able to inform us a bit about that?

This college watch, partially, is what I got here to watchmaking college to do. It’s the proper mixture of the abilities I needed to study, observe, and showcase multi function undertaking. It’s an ETA 6497 base, like most college watches these days. The escape wheel bridge and prepare bridge have been each totally fabricated utilizing lathes solely; there may be completely no CNC used on college initiatives. The main focus of this undertaking for me particularly was aesthetics and ending, in order that’s the place it turns into distinctive and is basically capable of stand out. The edges of all the bridges within the actions have been solely formed by hand with a file. There’s a methodology you should use to chop good arcs into your bridges utilizing the lathe, however I actually needed to check my shaping abilities.

The bevels have been all shaped and polished by hand—their flatness and consistency in width was no straightforward feat to take care of. It’s removed from good, however the bridges have a few of my greatest bevelling work up to now. The entire prepare wheels are bevelled and satinized as properly. It has polished countersinks, black-polished and bevelled screws, nickel-plated bridges and wheels, and snailing on the crown and ratchet wheel, all of which took some time to determine learn how to execute with a high-quality finish outcome. I attempted to make use of as many floor finishes as I may as properly. The bridges have perlage on the underside, are media blasted on the edges, bevelled, mirror polished, and completed with Geneva stripes on the highest. I attempted to maintain the motion as monochromatic as attainable by plating every little thing in nickel, leaving the wealthy crimson/purple hue of the jewels as the one pop of color. This concept got here from Uhren-Werke-Dresden (UWD) actions and hoping to attain an identical aesthetic outcome.

Contemplating you continue to have a while to go earlier than commencement, and this makes use of your school-provided dial, what are your plans for it?

For probably the most half, the watch is accomplished—no less than for my time at school. If I’m practising one thing like black sharpening and discover myself getting a greater outcome than I did after I polished the clicking or the screws, then possibly I’ll return and contact them up. I do plan on turning a stability workers for this watch; nevertheless, I’m anticipating that to be a number of months away nonetheless. I additionally plan on making a really sophisticated and ornate dial for this watch. Nonetheless, I’m anticipating to do this after commencement, as I’ll possible have entry to extra specialised equipment and data than I do at the moment.

As soon as that dial is completed, what comes after that?

As soon as the dial is completed, the watch is completed. The one manner ahead is to make one other watch and one-up myself. I feel the easiest way to do this is to take my time and manufacture the entire motion from scratch. If I’m going by means of that effort, nevertheless, it definitely gained’t be a 6497 or 6498 base. As a substitute, it’ll be one thing I design from scratch. It is going to be fairly an enterprise, however then once more—that’s not a undertaking I’d plan on ending in only a few months.

What do you see your self doing sooner or later? What concepts do you might have for a primary watch, for example?

I see myself working in an unbiased house quite than working for a bigger firm. I’m capable of acknowledge that the fashion of labor completed in bigger services doesn’t foster the concepts and pursuits I’ve inside watchmaking in addition to being at an unbiased model would. There’s a meteoric uprise of American watch manufacturers popping up as we communicate, and lots extra of their improvement levels to return. I see that market rising an unbelievable quantity within the subsequent 5 to 10 years, so if the watch market permits it, that’s the place I’d prefer to be.

How can individuals preserve monitor of your progress as a watchmaker?

All of my watchmaking progress is usually uploaded on my Instagram account: @hudsonmickeymanguy. I’m certain that sooner or later, I’ll department out to different platforms, however Instagram is the place I’m most lively and accessible. Any vital progress in my pursuits is posted there, so if you wish to see what I’m as much as, that’s the place you will discover it.